A raw material that can be machined with high precision, suitable for finishing operations where good surface finish and dimensional accuracy are required. Reduced boundary wear and a smooth finish with excellent surface smoothness. A versatile raw material for general hardened steel fabrication. A metal coating with strong adhesion characteristics has been selected to reduce delamination, allowing for smoother production and longer tool life.

The optimised solution enables efficient boring of common steel.

? High strength peripheral cutting edge

? Relatively large edge processing

Tool drawing number: 070042

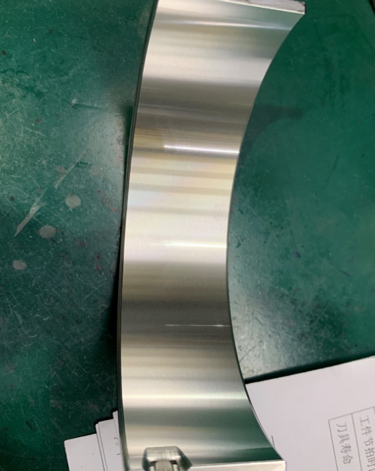

Workpiece name: Shaft shank

Workpiece material: lead-copper alloy

Workpiece diameter:φ110

Roughness:Ra0.8

Machining method: Boring

Machining process: Boring of inner arc surface